TECHNOLOGIES

Plastic Injection

29 Engel presses ranging from 25 to 260 T

6 “BabyPlast” presses for prototyping and small productions

Automatic centralized dehumidifying and conveying system for plastic materials

Vertical presses operated by worker or robot for overmoulded products

Robots used for manipulation of components and finished products

Injection of nylon (PA6 GF30, PA66 GF30, PA6T/66-GF33, …), PPA (Amodel AS1133HS, AS6115HS), PBT, Polypropylene (PP T20, PP T40, …)

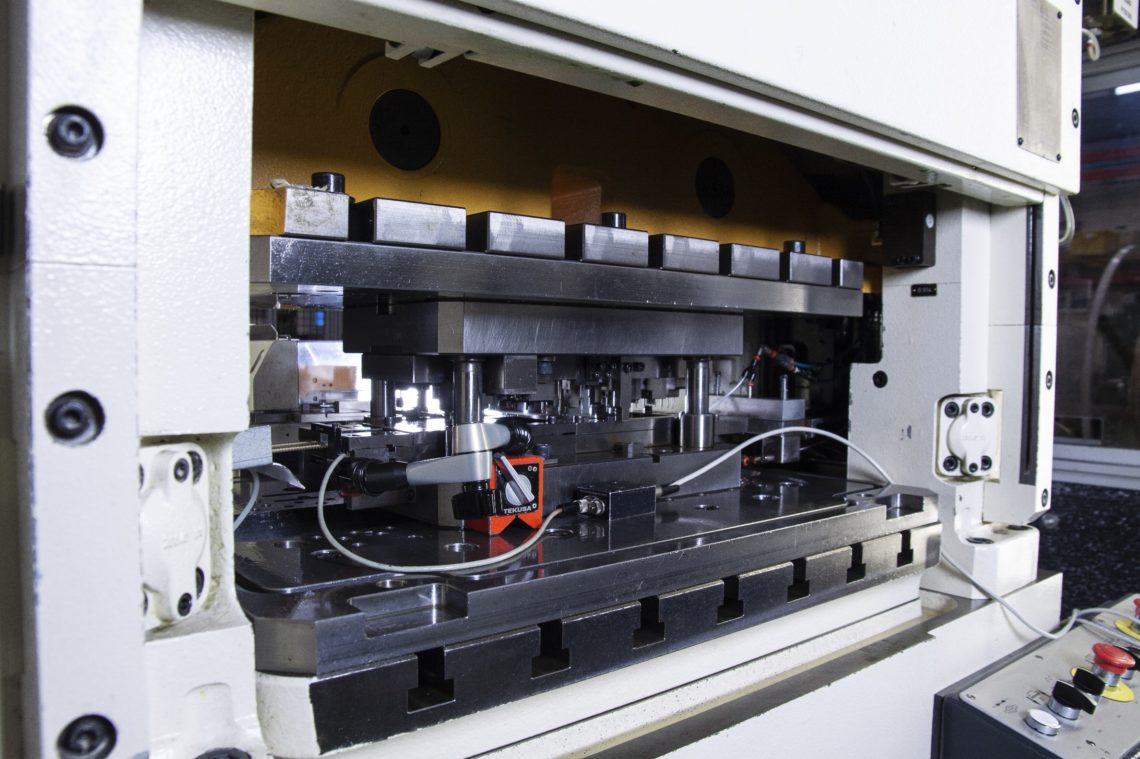

Metal stamping

8 Bruderer staming presses from 18T to 40T

1 Omera press 150T

1 Omera press 150T

High speed stampingz

100% quality checks using high precision cameras

Automatic reels system

Supply for metal wire processing

Stamping of brass, bronze, CuNiSi, CuFe2P, stainless steel

Wire cutting and crimping

4 wire cutting and crimping machines

100% quality checks with load cells

Quality checks by micrographs

O-ring automatic insertion

Main application on bulb holders

Support for the development of new terminals

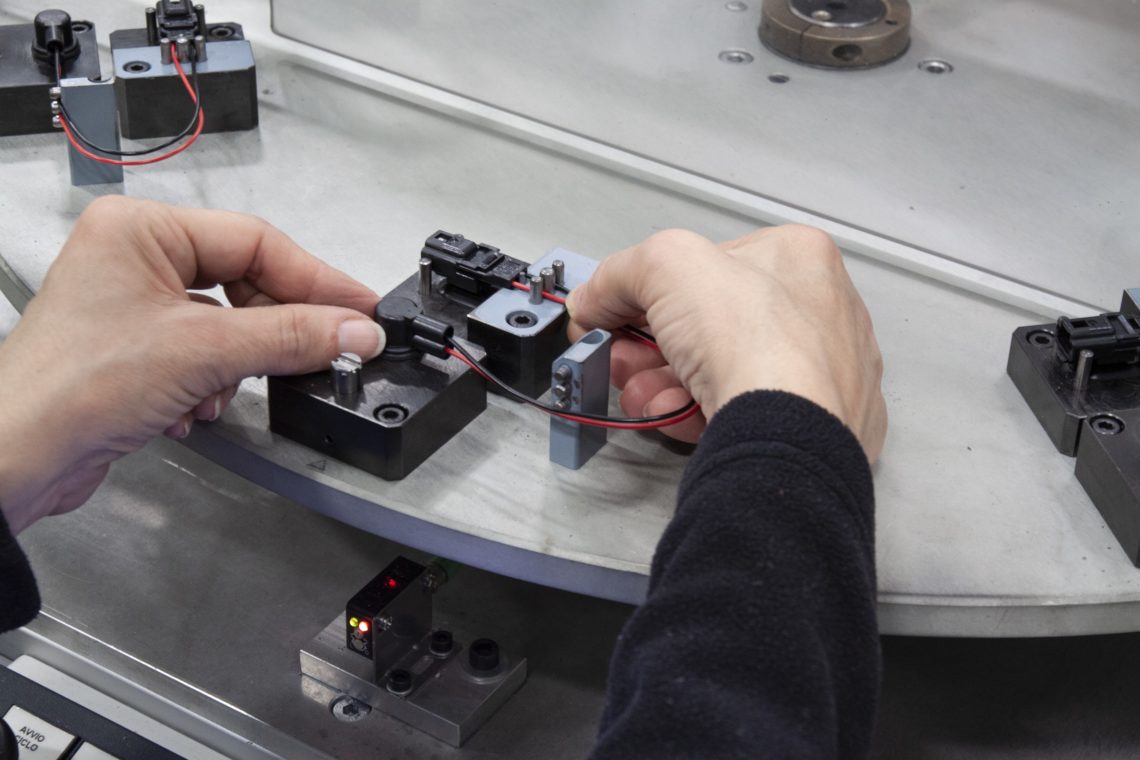

Assembly

More than 50 assembly tables/lines

Automatic electrical, mechanical and visual quality checks

24h shifts production

Process industrialization and assembly equipment realization

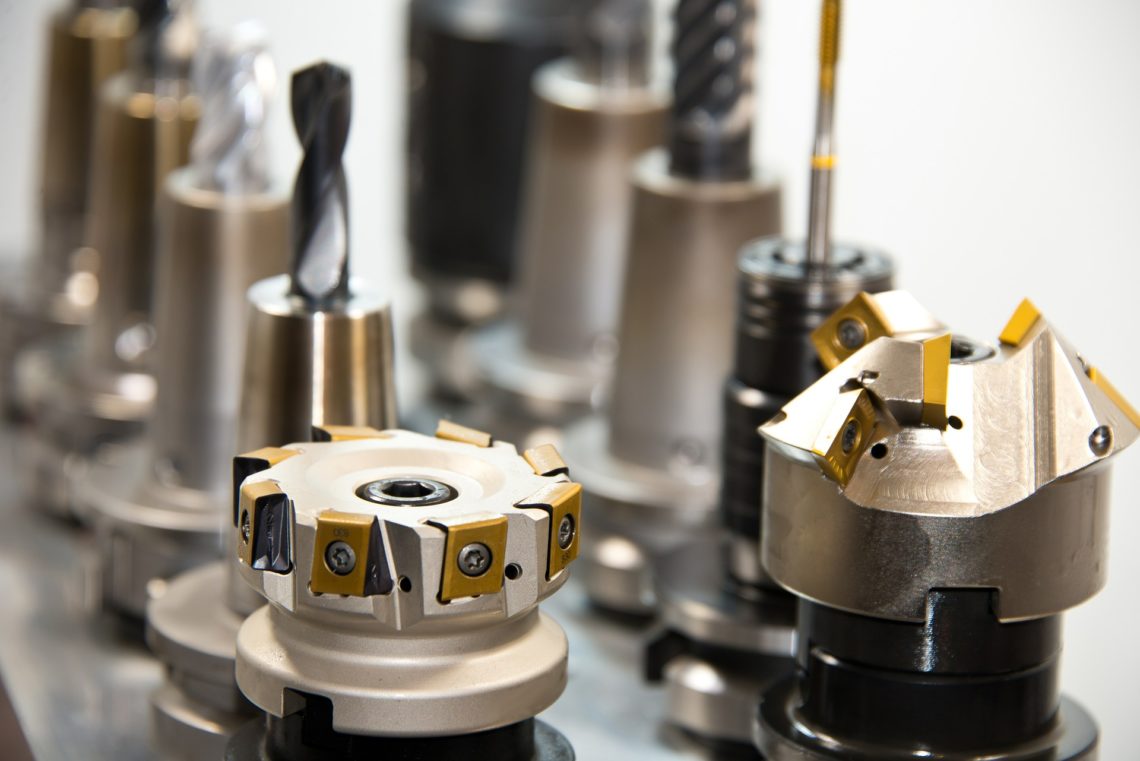

Toolshop

This department rests its solid foundations on the design and manufacturing experience of our technicians and employs technologically advanced machines, such as high-speed CNC milling machines and last-generation electro-erosion machines.

We produce highly sophisticated moulds, injection moulds and automatic assembly tables.